Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: BB15058555

Brand: BRANDO

Voltage: AC220V/DC24V

Insulation Class: H

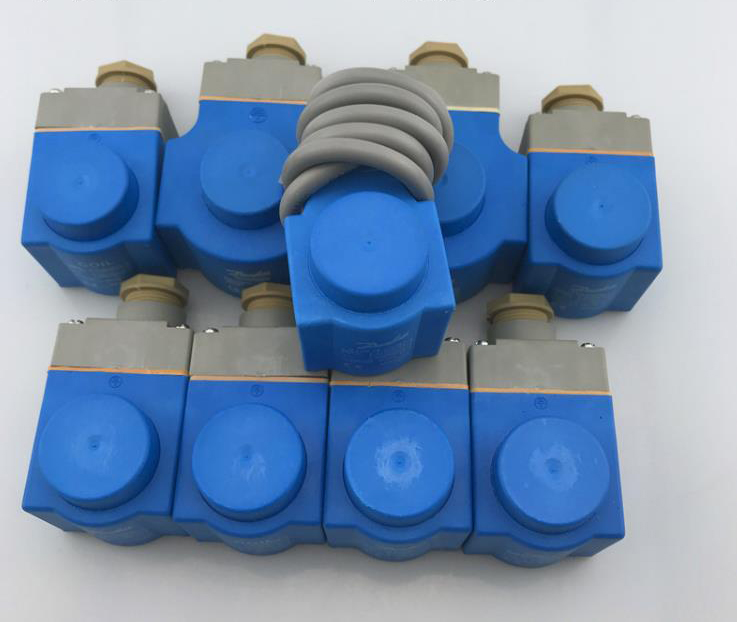

Name: Flying Leads Refrigeration Solenoid Coil

Application: EVR Series Chiller Refrigeration Components

Hole: 15mm

Type: Solenoid Electric Coils

Connection: DIN Type Wire Lead Electromagnetic Coils

Power: AC:18VA DC19W

Weight: 310 G

Height: 58.5mm

Packaging: Box Carton Pallet

Productivity: 60000 sets/ 1 week

Transportation: Ocean,Land,Air

Place of Origin: NINGBO CHINA

Supply Ability: 250000 sets/ 1 month

Certificate: CE,GB

Port: Guangzhou,Ningbo,Shanghai

Payment Type: L/C,T/T,Paypal,Money Gram,Western Union

Incoterm: FOB,CFR,CIF,EXW

Flying Leads Refrigeration Solenoid Coil

The working principle of the Solenoid Valve Coil is the principle of solenoid induction. When the coil is energized (DC or AC), a current will pass through the coil, and a magnetic field will be generated. The magnetic field will drive the Solenoid Valve spool to be attracted to generate corresponding action. When the spool moves to the left or right, the passage will be opened. The solenoid valve is divided into a direct-acting solenoid valve according to the principle, a direct-acting solenoid valve, and a pilot-operated solenoid valve.

Each solenoid valve is equipped with an electromagnet, and the solenoid coil of the electromagnet is energized, and the solenoid force is sucked to push the upper and lower opening and closing movements of the valve core, thereby realizing the switching of the solenoid valve. The solenoid coil of the electromagnet is de-energized, and the spring restoring force pushes the spool to slide in the opposite direction. The power and de-energization of the solenoid valve coil causes the electromagnet to pull and release the valve core, so that the spring compresses and relaxes, thereby pushing the spool to slide back and forth. In the sliding movement of the spool, the different oil passages on the valve body are opened and closed to perform the switching operation of the valve to change the flow direction or the oil passage. The on/off of the solenoid coil power supply of the solenoid valve itself is completed by the contact action of the contactor or the relay. In other words, the solenoid valve must be used in conjunction with a contactor or relay.

Technical data of flying lead EVR series refrigeration solenoid coils:

Model Numbers BB15045010 BB15058555 BB15045054

Normal voltage AC220V/DC24V

Normal power AC:11VA DC10W AC:18VA DC19W AC:25VA DC16W

Insulation class H, F

H

Connection type DIN43650

Application EVR series Refrigeration Solenoid Valve

Weight 314 g 310 g 487.5 g

Three type of EVR Series Chiller Refrigeration Automatic Control Components Coils:

Automatic winding machine with AC220V/DC24V 15mm Hole Solenoid Electric Coils:

Transaction processing of DIN Type Wire Lead Type Electromagnetic Solenoid Coils:

Refrigeration solenoid valve working principle

When the coil is energized, the refrigerating solenoid valve forms a magnetic field, sucks up the iron core, and the pilot valve opens, so that the pressure acting on the upper part of the piston is lowered, thereby pushing the piston upwards by the pressure difference to make the pipeline unblocked; when the coil is de-energized, the iron is broken. The core drops due to its own weight and spring action to close the pilot valve. At the same time, the pressure medium flows into the upper chamber through the piston orifice, and the piston's own weight and spring pressure cause the piston to fall to the valve port, thereby cutting off the nozzle.

Causes and troubleshooting of the Solenoid Valve For Refrigeration:

1. When the solenoid reversing valve coil is open, shorted or burned out, the valve core cannot be sucked, causing the slider to not move. Should be replaced.

2. The armature of the solenoid valve for cooling is stuck, the valve core cannot move, and the slider does not move. The valve body cleaning adjustment can be turned on.

3. When the power supply voltage is lower than the rated value of the cooling solenoid valve, the pressure difference between the inlet and outlet of the solenoid valve exceeds the valve opening capacity. At this time, the valve often emits [da~da~" noise, causing the valve core to not close. The power supply should be improved.

4. The flow of the solenoid valve for cooling is reversed, causing the valve core to not operate. The flow should be adjusted.

5. The system is hot, high pressure and impurities inside the machine, causing the slider to deform and become stuck. Should be replaced as well.

6. The residual magnet is sucked into the valve core or the valve core is stuck. After the power is turned off, the cooling solenoid valve cannot be closed. Cleaning adjustments, such as no effect replacement.

7. The solenoid valve seal for cooling is damaged or the fastening screws are loose, causing refrigerant leakage. Replace the gasket and tighten the screws.

8. The capillary on the valve is blocked or broken; or the system is seriously leaked and the slider does not move. Clean the capillary or use a copper tube that is slightly thicker than the broken capillary.

9. The valve has dirt, valve seat or valve needle damage and the spring force is too small, causing the solenoid valve to be closed. Clean and adjust or replace the spring.

In addition, if the internal leakage of the reversing valve causes the high-pressure refrigerant gas to leak to the low-pressure side and the normal pressure cannot be established at both ends of the reversing valve piston, the reversing valve should be replaced. If the pressure difference in the refrigeration system is too large to reverse the reversing valve, check the refrigeration system pressure or find the leak point and fill the refrigerant. If the four-way valve slide does not move or the action is not in place, use the end of the wooden handle of the screwdriver to check and judge, gently tap the valve body, and then turn on or off the AC 220V power supply, repeat several times, and hear the armature suction. When the sound is reversed and the gas in the valve body is commutated, it can be determined that the reversing valve is basically restored to normal operation.

Pls contract us for more details!

Product Categories : Solenoid Valve Coil > Solenoid Valve Coils

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.