Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: 4V210-08

Brand: OEM

Brand: Other

Customized: Customized

Certification: Other

Power: Pneumatic

Pressure: Medium Pressure

Work Temperature: Normal Temperature

Material: Aluminum

Packaging: boxes,cartons,pallets

Productivity: 100000pcs per month

Transportation: Ocean,Land,Air

Place of Origin: Ningbo,China

Supply Ability: 100000pcs per month

Certificate: CE.ISO

Port: Ningbo,Shanghai,Tianjing

Payment Type: T/T,Paypal,Western Union

Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

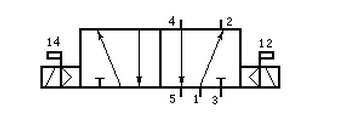

200 Series Pneumatic Control Valve 4V210-08

The 4V210-08 Pneumatic Solenoid Valve controls the opening and closing of the gas circuit to make the cylinder function. The on/off control of the Solenoid Valve is controlled by the TPC timing program controller. Timing control, position control, manual control and automatic control are possible through simple function settings. Wait for all the required operations. Our company also has corresponding cylinder products and filters. The company promises a one-year quality guarantee. The 4V200 series includes 4v210, 4V220, 4V230C, 4V230E, and 4V230P.

| Media | Air |

| Action | Internally piloted |

| Type | 5 way 2 position |

| Orifice size | 16mm2(CV=0.78) |

| Port size | IN-OUT 1/4"PT, Exhaust 1/8"PT |

| Lubrication | Not required |

| Pressure range | 1.5-8kgf/cm2 |

| Proof pressure | 12kgf/cm2 |

| Temp. range | -5~60° |

| Single electrical Control Power consumption | 3.0VA |

| Insulation | F Class |

| Protection | IP65 |

| Connection | Socket with plug |

| Max. frequency | 5 cycles/s |

| Min. activate time | 0.05 second |

The inner hole is processed by special technology with small friction resistance, low starting pressure and long service life. No lubrication required;

Can be integrated with the base valve set, saving installation space; Manual device is attached to facilitate installation and debugging; A variety of standard voltage grades are available.

First determine if the solenoid valve is faulty.

1. Test the pneumatic mechanism. When the power is cut off and checked to ensure that the air supply is normal, press the manual valve open button on the side of the solenoid. If the solenoid valve is open, the valve is normally open. If you leave the button to see if the solenoid valve is switched, if it switches normally, the Pneumatic Actuator of the solenoid valve works normally.

2. Test the electrical part. Manually rotate the switch on the field distribution box, switch the open position valve to open, and close the valve when closed, indicating that the electrical part is normal. If it is not working, measure whether the electromagnetic coil is burnt or not, and replace it.

Troubleshooting method: first check if the air supply is normal, if not, open the air supply valve. Then check whether the solenoid valve is normal and handle it according to the above-mentioned determination method. In an emergency, you can manually open the valve directly with the trachea.

3, solenoid valve maintenance precautions: 1, the piston rod must be flexible. Manually tested, it is easy to press the piston rod. After the hand is released, the piston rod can automatically return to the original position before pressing the spring force. If it does not pop up automatically, clean the dust inside the valve body and the piston rod and handle it with high-quality oil to ensure the piston rod is free. 2. The pilot valve piston should be able to move easily and freely like the piston rod. The treatment method is the same as above. 3. The gas path of the pilot valve must work smoothly. If it is not smooth, it can be used to comb the gas path to ensure smooth and unobstructed airway. 4. The electromagnetic coil is energized under normal conditions, the closing member should be lifted, and there is a sound of suction. If it is not normal to check whether the coil is burnt and if there is any debris inside the closing part, measure and clean up the debris.

Product Categories : Pneumatic Valve > Pneumatic Solenoid Valve

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.