Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: AD007

Brand: Brando

Die Casting Machine Type: Hot Chamber Die Casting Machine

Application: Auto Parts

Material: Aluminum Alloy ADC10, ADC12, A360, A380; Zamark, E

Certification: CE

Production Type: Die Casting

Material Standard: As Your Requirement

Packaging: Carton and pallet

Productivity: 3000000pcs/month

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 300000sets per month

Certificate: CE ISO

Payment Type: L/C,T/T,Paypal,Money Gram,Western Union

Incoterm: FOB

High Abrasion Resistance Aluminum Die Casting

High Abrasion Resistance Aluminum Die Casting For Pneumatic components parts is a process of injection of Aluminum or Aluminum Alloys under pressure. It provides EMI shielding, rigidity and durability with minimal weight for shields and housings for handheld devices.

Aluminum Die Casting Informations:

1. Material : Aluminum alloy ADC10, ADC12, A360, A380; zamark, etc

2. Features: High strength, high gas-tight, high abrasion resistance

3. Packaging Details: 15-20 kgs loaded in carton, then packed by pallet

4. Capacity: Die casting machine 120ton to 1200ton

5. Production capacity: 800pcs to 10000pcs per day, according to product types

6. Manufacture process: Die casting + remove flash + shot blast + finish machining + passivate + package

7. Surface Treatment: Polishing, Sandblasting, Painting, Powder Coating, Galvanizing, Chrome Coating, Anodizing

One imprssion of how we produce:

| Product | Aluminum die casting parts |

| Machine Delivery time | 30 to 45 days |

| Drawing Available | IGS, STEP, SLD, X-T, XDF, DWG, SAT, STL, etc |

| Material | Aluminum alloy A380 A360 ADC12, ADC14 LM22 LM24 AC-46100 AlSi9Cu3, Zamark, according to customer requirements |

| Manufactuering Process | Drawing and Sample...Mould Developing...Die Casting...Deburring...Drilling and Threading...CNC Machining...Polishing...Surface Treatment...Assembling...Quality Inspection...Packing...Shipping |

| Surface treatment | Shot blast + clean + passivate |

| Application Example | Pneumatic components parts; Led light housing; Led heatsink; Auto, motocyle, bicycle parts; Furniture accessories; Power tool housing; Pump housing; Mechanical parts, etc |

| Certificate | CE, ISO |

| Advantage | More than 10 years of experience in aluminum die casting, zamark die casting field; Professional long working ages casting working people; Experienced engineers; Fast response of after sale |

Some questions you may want to know:

Q1: How to get a accurate quotation?

1. Which alloy you use(Zinc alloy or aluminum alloy, etc)

2. The weight of parts

3. The packaging of products

4. A description of your processing requirements such as machining or surface treatment

Q2: What is your material for moulds:

H13,3Cr2W8V,4Cr5MoVlsi,SKD61,8407#, also can be supplied by your request

Q3: What kind of the materials can be provided?

Aluminum alloy, zinc alloy, Zamak, and so on

Q4: What`s the thickness for anodizing? Can you do 15um?

Our normal thickness is about 10 um. Yes, we can do 15um and above.

Q5: What`s the delivery time for samples and mass production?

1, 2-3 weeks to open the new moulds and make free samples.

2, 3-4 weeks after receipt of deposit and confirmation of the order.

About Service:

1. If any problem occur during production or you meet quality problem when you are using our goods, inform us at once, we will offer you best solution

2. We offer professional order operation service: Same sales person follows the order from discussing step to the end of you get the goods of order

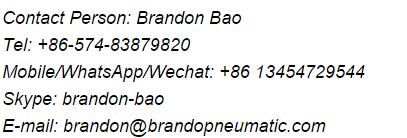

3. Contact us via email, phone calling, skype, or other chatting methods, we will response at once

Photo of the Aluminum Die Casting:

We can also produce other kind of aluminum die casting.

Other Aluminum Die Casting and the Package:

If you are interesed in our products or want to buy, welcome your contact and you can ask any questions you want to know.

There are some contact informations:

Product Categories : Aluminum Die Casting

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.