Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: DMF-ZL-B

Brand: Brando

Actuator: Pneumatic

Connection: G3/4'' Inlet Port

Structure: Angle Type Diaphragm Valve

Pressure: Ordinary Pressure

Function: Solenoid Valve

Usage: Emptying

Standard: DIN

Name: DMF-ZL-B Economical Pulse Jet Valve

Action Type: Normally Close Internal Pilot Pulse Valve

Packaging: Box Carton Pallet

Productivity: 165000 sets per month

Transportation: Ocean,Land,Air

Place of Origin: Ningbo China

Supply Ability: 41 thousand sets per week

Certificate: CE,GB,ISO

Port: Yiwu,Shanghai,Tianjin

Payment Type: L/C,T/T,Paypal,Money Gram,Western Union

Incoterm: FOB,CFR,CIF,EXW

DMF-ZL-B Economical Pulse Jet Valve

A complete bag filter is assembled with many types of bag filter accessories. The operation of each bag filter directly determines the working efficiency and dust removal of this bag filter. The effect, so we can find out the problems of the accessories in time when using the bag filter.Bag-type dust collector accessories often encounter problems during use:

1. Electromagnetic DMF-ZL-B pulse jet valves often have problems during use, such as leakage of the diaphragm of the Solenoid Valve, burning of the coil, and stucking of the moving iron core.

2. The dust filter bag will often have problems during use. For example, the dust filter bag is clogged, peeled off, worn, and aging. These should be replaced in time.

3. The Pulse Controller is damaged during use. The problems that often occur are the failure of the control system and the burning of the board.

The problems frequently seen in bag dust collectors are mainly the problems of the above three types of dust removal accessories. We should regularly check the use of these accessories during the use process and replace them in time to ensure the long-term stability and reliability of the bag filter working.

Technical parameter of DMF-ZL-B Aluminum body economic pulse jet valve:

Model Number DMF-ZL-B Operating Medium Compressed air Valve Type Economical right angle pulse valve Blowing Area 3.5-6㎡ Inlet & Outlet Port Size G3/8'' Inches; φ27 Diaphragm Service Life Over 1,000,000 cycles Voltages AC110V/AC220V; DC24V Relative Humidity ≤85% Working Pressure 3-8Bar; 0.3-0.8MPa Environment Temperature -5℃-55℃

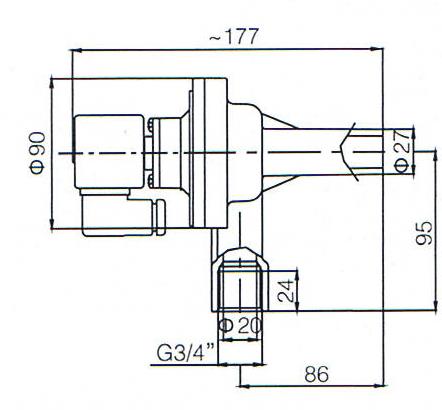

Main dimension of DMF-ZL-B Right Angle Type G3/4'' inlet threaded Port pulse solenoid valve:

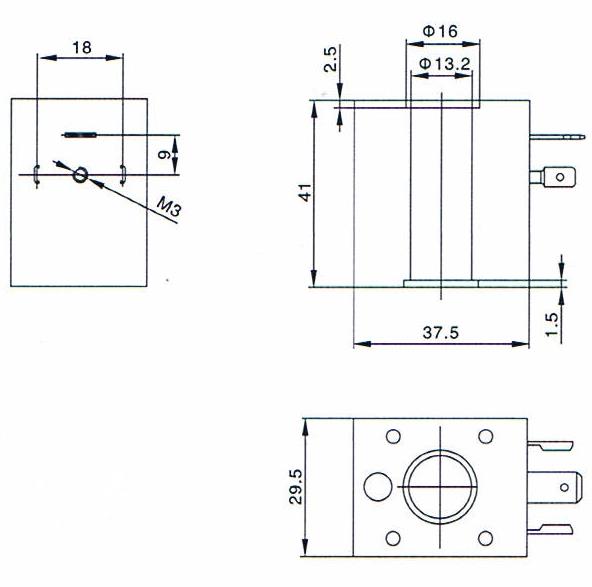

DMF-ZL-B Electromagnetic Pulse Controlled Diaphragm Valve 24VDC/220VAC solenoid coils dimension:

Production display of DMF-ZL-B Normally Closed Internal Piloted Jet Solenoid Pulse Valves:

Air box pulse bag type dust collector with DMF-ZL-B pulse jet valves:

The air box pulse bag type dust collector introduces a new type of dust collector with the first selected level, which combines the advantages of the chamber backflushing and pulse jet cleaning and other dust collectors, and overcomes the pulse blowing and cleaning and filtering simultaneously leading to cleaning. The disadvantage of poor effect expands the application range of the air bag pulse bag type dust collector.

Structural features:

This is a type of chamber structure assembling type, which is a bag type dust collector which performs pulse-cleaning of the chamber air-cooling box (so-called off-line cleaning) by the chamber top pulse valve for each chamber filter bag. It is different from the cleaning of the general blown dust collector. In the same filter chamber, only the filter bags of each row are sprayed and cleaned (that is, so-called online cleaning), and the other rows are arranged. The filter bag is still filtered. That is to say, the cleaning and mixing are carried out in one chamber at the same time, and the dust under the ash is flying twice, and some of the dust is collected by the adjacent filter bag, which is not suitable for gas filtration with a large dust concentration. The PPC type air bag pulse bag type dust collector is carried out under the condition that the indoor valve is stopped and filtered, and the cleared dust is settled downward in the ash half, and does not generate secondary flying, which is very advantageous for filtering the gas with a large concentration of dust. Moreover, the filter bag of one chamber can be replaced without stopping the machine.

The gas box pulse dust collector is divided into four series according to different bag numbers: 32 bags/room, 64 bags/room, 96 bags/room, 128 bags/room. Each series is divided into various specifications according to the number of rooms. A total of 33 kinds. The structure is detailed in the attached drawing, which consists of the following parts:

(1) Housing part: including clean room (or gas purifying box, box), filter room, compartment partition, access door and housing structure. There is a poppet valve and a flower board in the clean room, and a short pipe is sprayed: the filter chamber has a filter and a skeleton.

(2) Ash bucket and dust discharge mechanism: There are ash buckets and screw conveyors, air conveyor chutes and rigid impeller dischargers (ash discharge valves) according to different series and different imported dust concentrations.

(3) In and out of the wind box body: including the inlet and outlet air ducts and the middle partition. The single row (or single row) structure is arranged on one side of the casing, and the double row (or double row) structure is arranged in the middle of the casing: the 32 series is small and has no box body, and the inlet and outlet air pipes are respectively connected to the ash bucket and the clean room. .

(4) Pulse cleaning device: including pulse valve, air bag, cylinder for poppet valve and its solenoid valve.

(5) Compressed air line and pressure reducing device, oil water separator, oil mister, etc.

(6) Pillars and vertical cage ladders and railings.

Welcome to your inquiry!

Product Categories : Dust Collector Pulse Valve > Pulse Jet Valve

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.