Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: D62

Brand: OEM

Material: Other

Customized: Customized

Certification: CE

Power: Pneumatic

Pressure: Medium Pressure

Brand: Other

Work Temperature: Normal Temperature

Packaging: pp bag inside, carton box outside

Productivity: 100000pcs per month

Transportation: Ocean,Air

Place of Origin: Ningbo,China

Supply Ability: 100000pcs per month

Certificate: CE.ISO

Port: Ningbo,Shanghai,Tianjing

Payment Type: L/C,T/T,Paypal,Western Union

Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

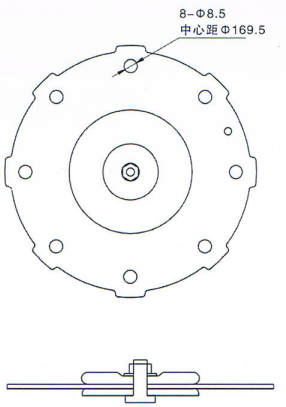

Industry Dust Collector Parts Pulse Valve Diaphragm D62

Pulse Valve Diaphragm is a whole piece of rubber diaphragm, which is installed with riveting head for sealing the air outlet of compressed air pipeline or plugging valve, the discharge and unloading hole and the bolt hole for fixed support around, and is the key control component of electromagnetic pulse valve. Is the electromagnetic pulse valve air switch, electromagnetic pulse valve diaphragm control pressure gas quickly discharged. Diaphragm front control pressure gas will lift the diaphragm, open the electromagnetic pulse valve channel into the bit on the injection, the electrical signal disappears, the electromagnetic pilot head of the spring make the moving column immediately reset closed unloading hole. Electromagnetic pulse valve diaphragm control gas pressure and diaphragm spring force after close the channel, the electromagnetic pulse valve to stop the resistance of injection on the diaphragm hole, when the guide head moving column is raised, when gas pressure unloading, electromagnetic pulse valve diaphragm have the effect of air resistance, when unloading closed cavity, after pressure gas is quickly to make the electromagnetic pulse valve diaphragm close the channel, stop blowing.

| Model | DMF-Z-62S Pulse Valve Diaphragm |

| Center distance | φ169.5 |

| Application | Dust Bag Filter System |

| Hole number for mounting | 8 |

| Working temperature | -20℃--80℃ |

| Working pressure | 0.2Mpa-0.6Mpa |

| Working medium | Clean Air |

| Diaphragm working life | More than 1 million cycles |

| Name | NBR Diaphragm |

| Material | VITON, NBR, HNBR, EPDM, FPM/FKM, SILICONE, CR |

| Feature | Resistance to oil,water, abrasion |

| Standard | Standard or Customized according to your need |

| Color | As per your request |

| Size | standard or as your design |

Drawings of Diaphragm DMF-Z-62S Shows the Digital Information

Application in the Bag Dust Filter System

We Guarantee Every Step of Producing and Testing Must be 100% Controled

The technical requirements of the Pulse Valve Diaphragm

Due to pulse valve diaphragm needs from time to time opening and closing action is a flexible mechanism to control the air circulation, has good flexibility and requirements, also demanded the sealing as high as possible, so the pulse valve diaphragm material is directly related to the service life of pulse valve diaphragm and using effect, in other words, the pulse valve diaphragm is good or bad will directly affect the working stability of pulse bag filter soot cleaning system, is directly related to the use of dust removal equipment cost, general pulse valve diaphragm has the commitment, the number of service life or actions using high-quality pulse valve diaphragm can directly reduce the cost of the use of dust removal equipment.

Instruction and Notice of Operating

1, Diaphragm (rubber or fabric reinforcement in rubber diaphragms) is a precision functional part used for checking pressure or changing fluid pressure into driving power

2, Diaphragm has been widely used in automobiles, controllers, household gas facilities and appliances with form of pressure sensors, actuators, On-Off switchs

3, Fabric-reinforcements in rubber diaphragms utilize a layer of an engineered fabric material as parts of the diaphragm construction. This layer of fabric give tremendous design felxibity

4, A very thin-walled diaphragm can withstand high pressures while remaining very flexible and responsive to minior pressure variations

5, Fabrics made of polyester, nylon and silk ard commonly used for most applications, fabric used for those applications exposed to high temperature. For those applications that require extremely high strength

6, All types of elastomers, such as nitrile, EPDM, fluorocarbon, neoprene, silicone, fluorosilicone, can be used in the fabric-reinforced diaphragms.

7, Fabric-reinforced diaphragms offer advantanges of no leakage, no lubrication, no breakaway force, no friction, high strength, functionality over wide pressure ranges, low cost, simple design, versatility

Product Categories : Valve Diaphragm > Other Pulse Valve Diaphragm

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.