Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: MSV-1099/9

Brand: Brando

Actuator: Electric

Material: Brass

Usage: Temperature Control

Standard: GB,CE

Valve Structure: Diaphragm Structure

Services Life: 100,000 Cycles

Application: Central Air-conditioning,freezer,cooler

Coils: AC/DC

Working Pressure: 3.0mpa

Temperature: -35-105℃

Packaging: Pallet,Carton,Boxes

Productivity: 1050 sets/ 1 week

Transportation: Ocean,Land,Air

Place of Origin: NINGBO CHINA

Supply Ability: 4250 sets/ 1 month

Certificate: CE

Port: Shanghai,Shenzhen,Tianjin

Payment Type: L/C,T/T,D/P,Paypal,Money Gram,Western Union

Incoterm: FOB,CFR,CIF,EXW

MSV-1099/9 2 Way Solenoid Valve In Refrigeration

Our MSV-1099/9 Refrigeration Solenoid Valve is the automatic control parts in refrigeration system.We supply wide choices of coils for AC/DC and connection sizes.The seals we use can be operated normally at temperatures as low as -40℃.We can provide products with different materials,different voltages or different pressure resistance.Meanwhile,we offer ODM/OEM services to meet your specific demands.

Technical information of MSV-1099/9 Refrigeration solenoid valve in wine cooler machines:

Model number MSV-1099/9 Connection size G 1 1/8'' Refrigerants CFC,HCFC,HFC Media temperature -35℃-105℃ Max. working pressure 2.5 mpa Min. working pressure 0.05 mpa Operating pressure 3 mpa KV value 5.7 (m³/h) Length (mm) 106 Width (mm) 216

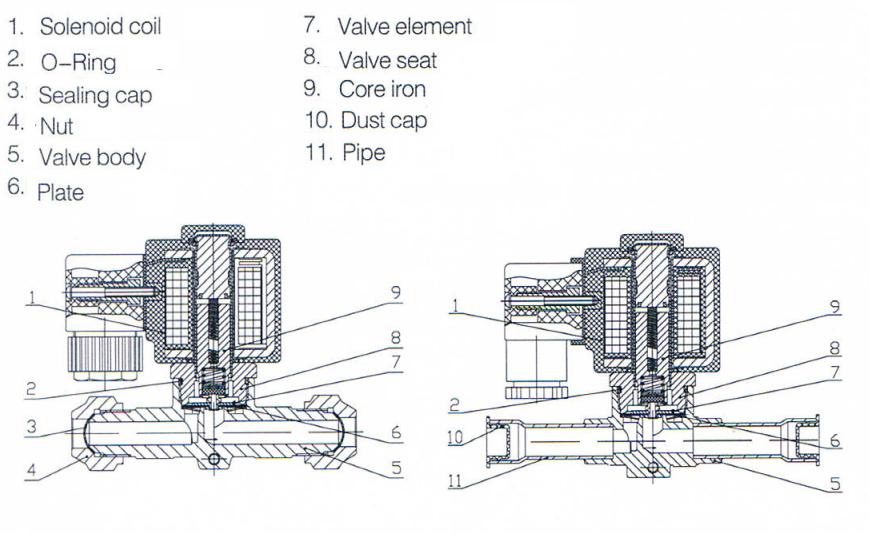

Main parts diagram of MSV-1099/9 Refrigeration solenoid valve in freezer equipment:

Production environment of MSV-1099/9 solenoid valve for control the refrigerants:

Packing and delivery of MSV-1099/9 1 1/8'' refrigerant control solenoid valve:

Central Air-conditioning with MSV-1099/9 refrigeration solenoid valve for liquid,suction,hot gas line:

The components of the central air-conditioning unit system include central air-conditioning air treatment equipment, central air-conditioning cold or heat source, central air-conditioning air system, central air-conditioning water system, central air-conditioning control, regulating device, central air-conditioning duct unit, and air-cooled cabinet.

First,Central air conditioning air treatment equipment:

Its function is to process the air supply air to the required state, in various forms, such as: fan coil, ceiling air conditioner cabinet, new air blower group, etc., belonging to the indoor end equipment of the air conditioning system.

Second, the central air conditioning cold source or heat source:

Its function is to provide the cold source and heat source required by the air conditioning system. The cold source is the equipment used to supply the air conditioning system with cooling capacity to cool the air supply air in the summer, that is, the air conditioning main engine, such as: air-cooled chiller (air-cooled module unit) , air-cooled screw unit and household central air-conditioning unit, etc.) and water-cooled chiller (water-cooled screw unit); heat source is equipment that supplies heat to the air-conditioning system to heat the air supply in winter, air-cooled heat pump air-conditioning unit and boiler.

Third, the central air conditioning system

Its function is to send the air supply air from the air treatment equipment (air conditioning end equipment) to the air-conditioned room through the air duct system (air supply duct), and at the same time, the corresponding amount of exhaust air is passed from the indoor to the air duct (the return duct or The exhaust duct is sent back to the air treatment unit for repeated treatment or discharged to the outside.

Fourth, the central air conditioning water system

Its function is to transport the cold air from the air conditioner main unit (cold source) to the end of the indoor air conditioner (air treatment equipment), and then send the heat absorbed by the end of the air conditioner to the air conditioner host from the end of the air conditioner. It includes: a chilled water system that delivers chilled water from an air conditioner to an air conditioner's end equipment and a cooling water system of an air conditioner main unit (for water-cooled chillers only). There is also a condensate system that concentrates the condensed water produced by the air treatment equipment during the cooling operation with organized discharge.

Fifth,Central air conditioning control and regulating device

Since the operating conditions of the air conditioning system should vary with the state of the outdoor air and the indoor conditions, it is necessary to adjust their working conditions frequently. Therefore, it must be equipped with certain control and adjustment devices. (Completed by air-conditioning installation project) GMV-R series digital multi-line group, GMV-P series inverter multi-line group and GMV-J intelligent multi-line group are direct direct evaporative type, so the engineering of such units generally includes the following Several systems:

1. The outdoor air conditioner main unit is the compressor and condenser of the air conditioning system.

2. The end of the indoor air conditioner is the evaporator part of the air conditioning system.

3. Connection copper pipe system between internal and external units.

4. Air conditioning duct system: The air treated at the end of the indoor air conditioner is delivered to the room where air conditioning is required.

5. Condensate system: Organized centralized discharge of condensate.

6. Control system.

The installation of the central air-conditioning duct unit, air-cooling cabinet unit and water-cooling cabinet machine project is basically similar to that of the multi-line group. The difference is that the installation of the connecting pipe (copper pipe system) is simpler, and the installation of the duct system is generally more. Some, at the same time, the condensate system and control system are simpler, and the water-cooled cabinet has more cooling water system. The installation and construction of such units is relatively simple, and is more easily accepted and recognized by the home machine dealers in the process of sales transformation to commercial units.

Welcome to your inquiry!

Product Categories : Refrigeration Solenoid Valve > Castel Type Solenoid Valve

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.